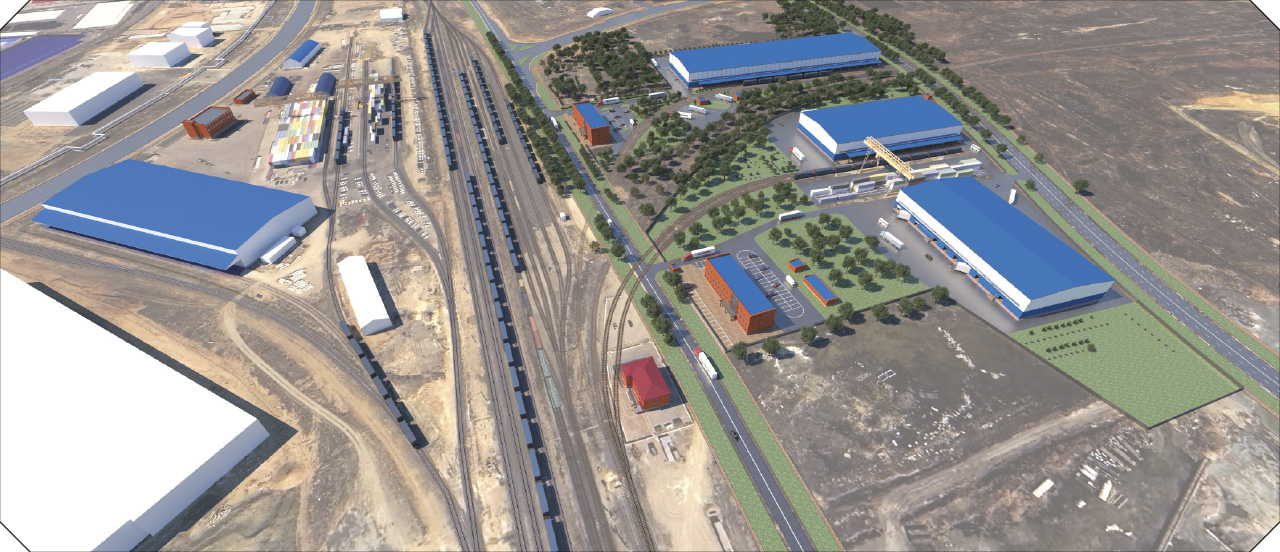

Technologies used at the TEMIRSERVICE station are aimed at optimizing transportation processes and ensuring high quality of service, which makes it an important link in the railway infrastructure of the region.

TEMIRSERVICE station has a receiving-departure and classification yards. To control the movement of trains and to organize shunting operations, the “Dnepr” microprocessor centralization of railway switches and signals (MPC) has been introduced at the station, all station yards are equipped with station yard bothway intercommunication, as well as administrative and managerial (operational) communication.